Operating conditions in cane sugar factories are changing everywhere the world – to such an extent that a fundamental review of the production concept has become necessary. One major aspect is automation.

01.07.2019

Automatically better

How automation can improve crystallisation results

Sugar factories in some countries are hoping for considerable financial gains by generating electricity from bagasse and feeding it into the local grid. Expectations are so high that sugar production is becoming less important, while the focus is shifting to maximising energy production and reducing steam consumption. For the operation of the sugar house, though, sugar quality is still the top priority. The following questions therefore arise: How can controlled crystallisation in automated vacuum pans help improve sugar quality? And what impact does automation have on steam consumption in the sugar house?

High expectations of controlled crystallisation

The real challenge in the operation of a batch vacuum pan and in the crystallisation process is controlled crystal growth, without secondary nucleation of the existing crystals, which would be detrimental to sugar quality.

Experiences in sugar factories have identified the first critical point in batch crystallisation after the application of the seeding material. A low crystal content combined with a small crystal surface can quickly result in high supersaturation and secondary nucleation. One effective corrective action is a stabilisation stage during which a low crystallisation rate is set for a specific time by keeping the heating steam pressure low. The small crystals can grow until they reach a suitable size to continue stable crystallisation.

The next step in crystallisation can then take place at a high speed. One frequently used method is to increase the dry substance content and massecuite volume simultaneously, while maintaining the defined crystallisation vapour pressure and applying the defined heating steam pressure.

What makes automation superior to manual operation

Although automation has many benefits for the pan station, experience has shown that many sugar factories prefer manual operation. Operators are typically unable to control crystallisation with optimum results. It is very demanding to constantly monitor measured quantities and continuously adjust the settings.

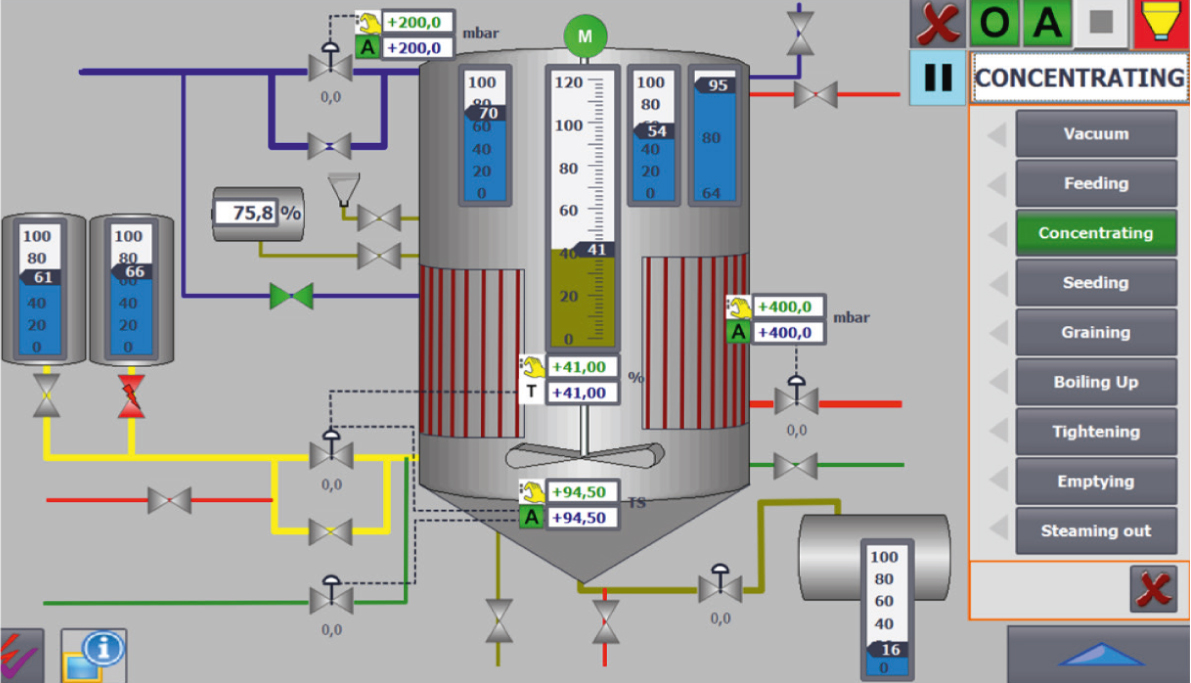

How is automation organised? An automated vacuum pan is controlled via an automation system with a human-machine interface (HMI). At least the four critical control loops for heating steam pressure, crystallisation vapour pressure, massecuite level and dry substance content should be automated. Access to these controllers for operation is via a user interface in the automation display system.

The functional link between the sensors and the control item (actuator) is shown schematically below. Even with a basic automation system, the machine operators can now concentrate on monitoring the process via the HMI during the crystallisation process. The number of manual interventions is considerably reduced. Further automation of the process is possible, even a fully automated pan cycle.

More sugar, better quality, less energy

The benefits of controlled crystallisation through automation are evident in the sugar yield, crystal quality, and energy savings – and a higher massecuite output.

Let’s look at the A product station in the sugar house of a factory in Russia. It was automated between the 2013 and 2014 production periods. The crystal content of the massecuite at drop time is a good indicator of the sugar yield from the entire station. In this project, automation of the vacuum pans raised the crystal content by an average of 4 percent.

This remarkable increase in the crystal content of the massecuite can be attributed to more even crystallisation. More evenly sized crystals would therefore indicate that there is a lower percentage of fine crystals, which lowers the viscosity of the massecuite. The vacuum pan can therefore produce massecuite with a higher crystal content at the end of the cycle, while using the same agitator power as before automation of the pan process.

In a cane sugar mill and refinery in Honduras, the vacuum pans were also automated and fed with crystal seed. This has improved the variation parameter for crystal size distribution from 44 to 28 percent. The percentage of fine sugar crystals is very low compared to manual operation: approx. 4 percent of crystals are smaller than 0.3 mm, with an average grain size of 0.67 mm. Thanks to the absence of small crystals, performance of the sugar dryer has improved. Another benefit: the sugar no longer cakes in the bags.

New ways of improving the heat balance

Maximum steam savings in vacuum pans can be achieved if no water at all is used during the crystallisation process. Since fine crystals cannot form during controlled crystallisation in an automated pan, there is no need to dissolve such crystals by adding wash water. This is an important detail in the overall energy consumption of the sugar factory, to keep steam demand low. A minimal use of water during boiling, and the option of using 3rd or even 4th vapour for batch pans opens up new ways of optimising the heat balance of the sugar process.

Improved control of crystallisation, particularly at the start of pan boiling, is essential for achieving a higher crystal yield, better sugar quality and lower energy consumption. The approach of using automation to prevent undesired secondary nucleation has been shown to be successful. For cane sugar factories, automation of the vacuum pans can be a first step towards a complete automation of sugar production.