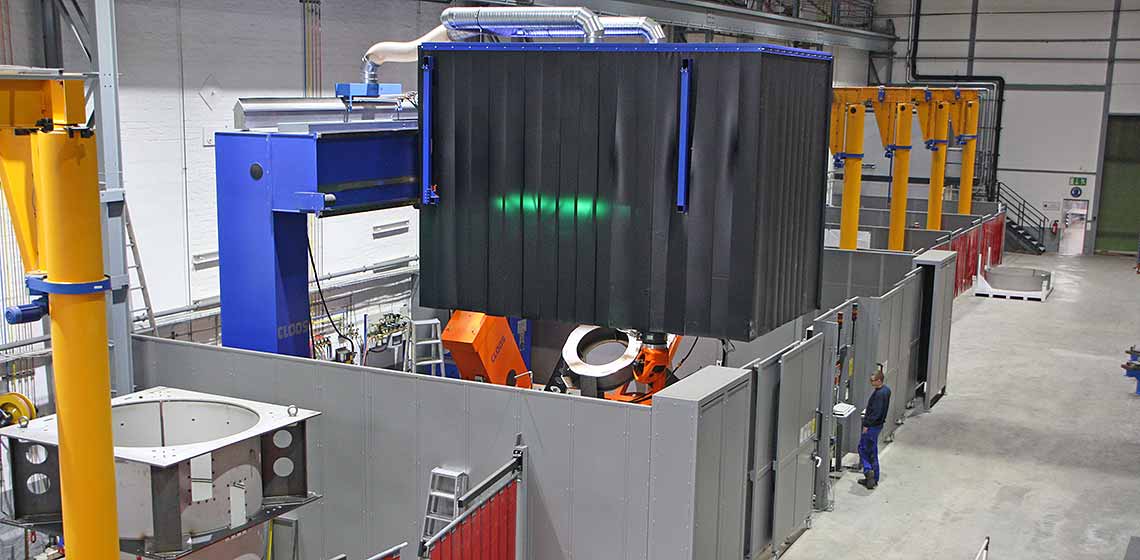

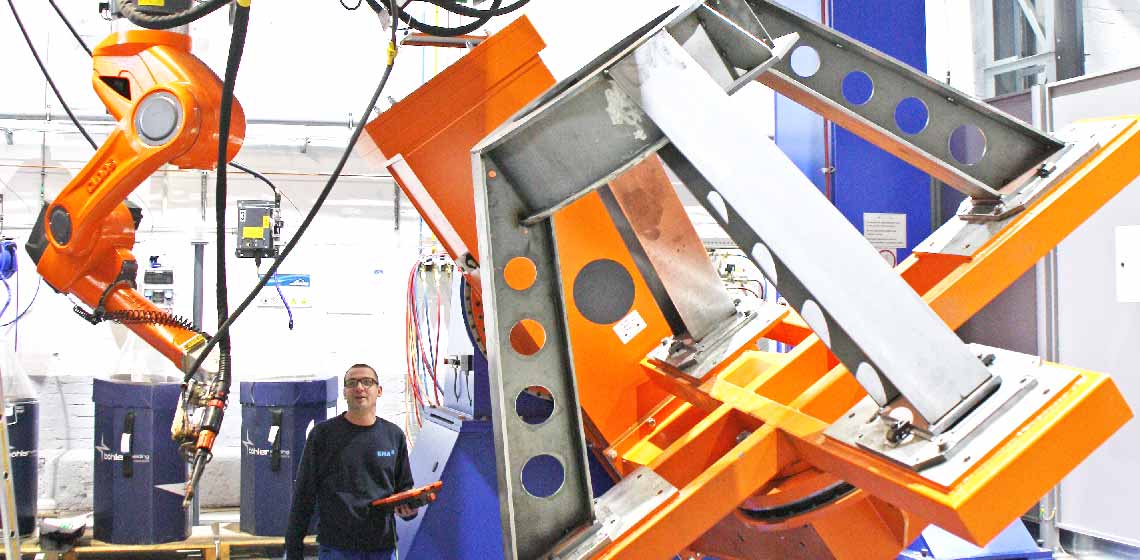

In our Braunschweig workshops, a robotic system that forms part of a new production line at BMA’s main site has recently taken over the manual welding of centrifugal housings and frames.

At Braunschweig, our new robot-based production line is now in operation, building large welded assemblies for centrifugals. They include the two K-series centrifugal housings and E-series centrifugal housings and frames, which BMA can now produce at the customer’s pace. The line’s heart and soul is a 2-station robotic welding system. At BMA, we believe in structuring our processes. An example: at an early stage, standard assemblies are assigned to a specific end customer, ensuring that they are available in time for the final assembly of the centrifugals. Needless to say that quality is of a consistently high level.