Safety inspections for centrifugal baskets. Subject to technical changes 07/2017

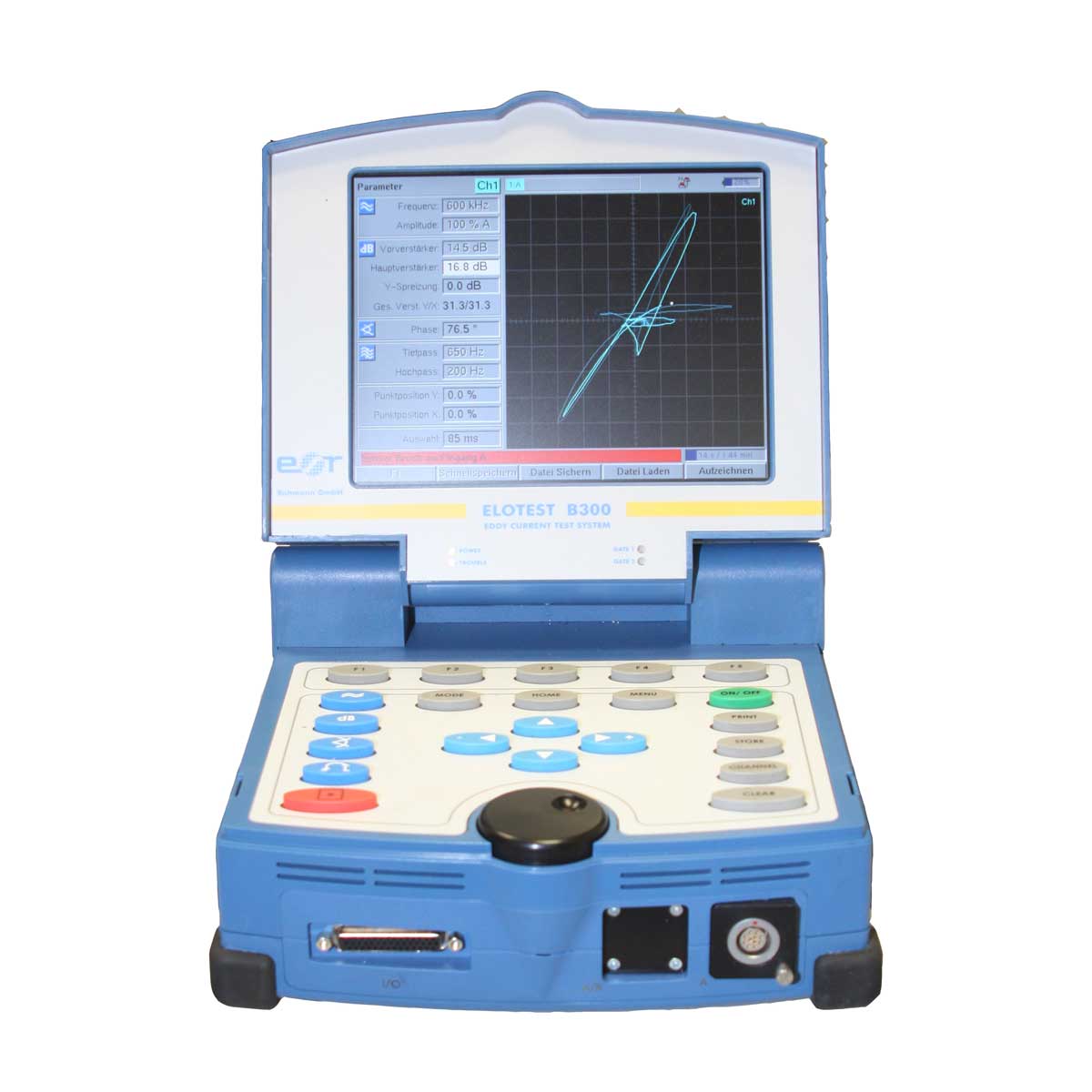

Eddy Current testing

In an instant. Non-destructive testing.

In many countries, centrifugals are installations that require inspection and as such they must be checked at regular intervals. Regardless of any legal requirements, we as centrifugal manufacturer urgently recommend our customers to have their centrifugal baskets regularly inspected by suitably qualified staff. Inspections focus on the boreholes, the weld seams and the basket hubs.

Benefits

- Inspections can be performed with the basket installed, achieving time savings of 50 % and more

- Considerably less disassembly work

- Compliance with legal requirements

- Greater operational reliability

Testing procedure

- Backing screen and cover screen are dismantled prior to testing

- Testing is performed by certified expert staff, in compliance with DIN EN ISO 9713

- Testing time required per basket: G and B series: approx. 5 hours, E series: approx. 8 hours

- After testing, BMA issues a certificate stating the condition of the basket