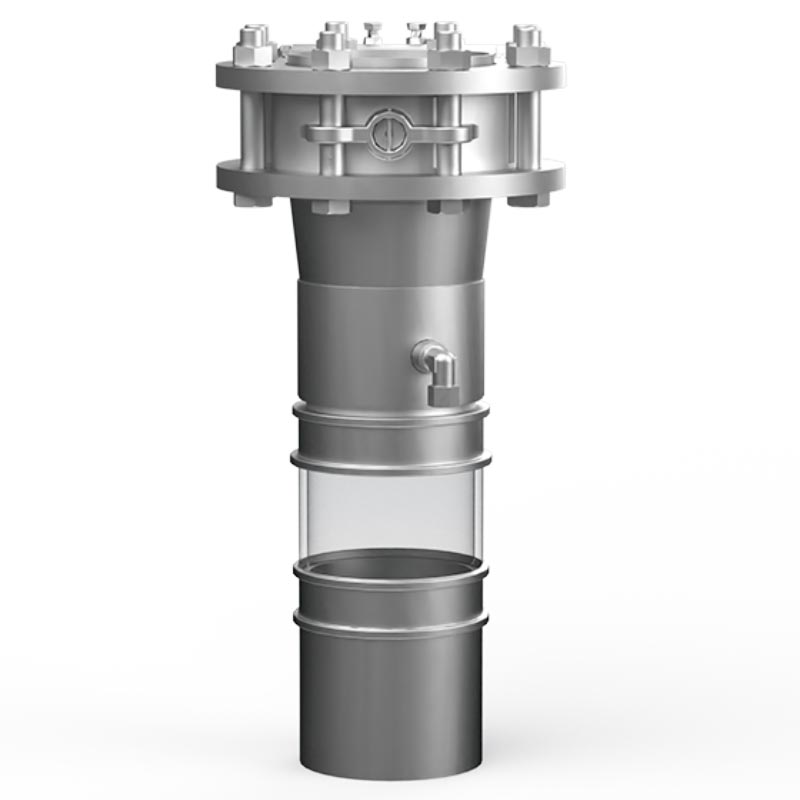

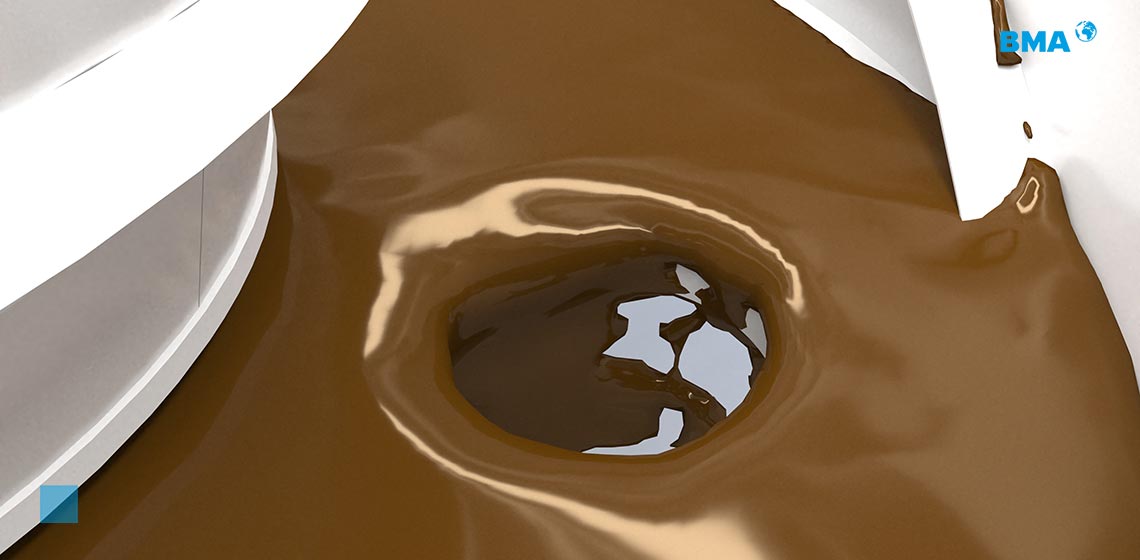

The massecuite enters the machine through the feed pipe, which is controlled by an electropneumatic valve, while the compensator permits a view of the massecuite flow into the machine.

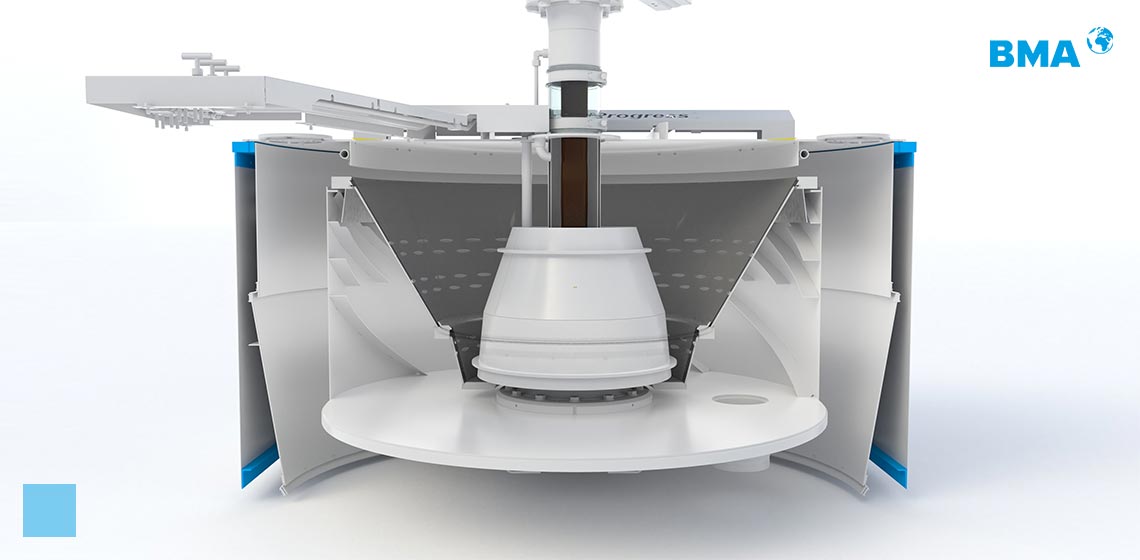

Operating principle K3300F continuous centrifugal

Compensator

An electropneumatic valve controls the massecuite inflow. The compensator isolates the centrifugal from vibrations and movements in the pipe. To ensure efficient massecuite preparation, the massecuite temperature is maintained by the addition of steam via the double-walled feed pipe, and water. The added steam also improves the flow behaviour of the massecuite. This permits continuous production and prepares the massecuite for separation.

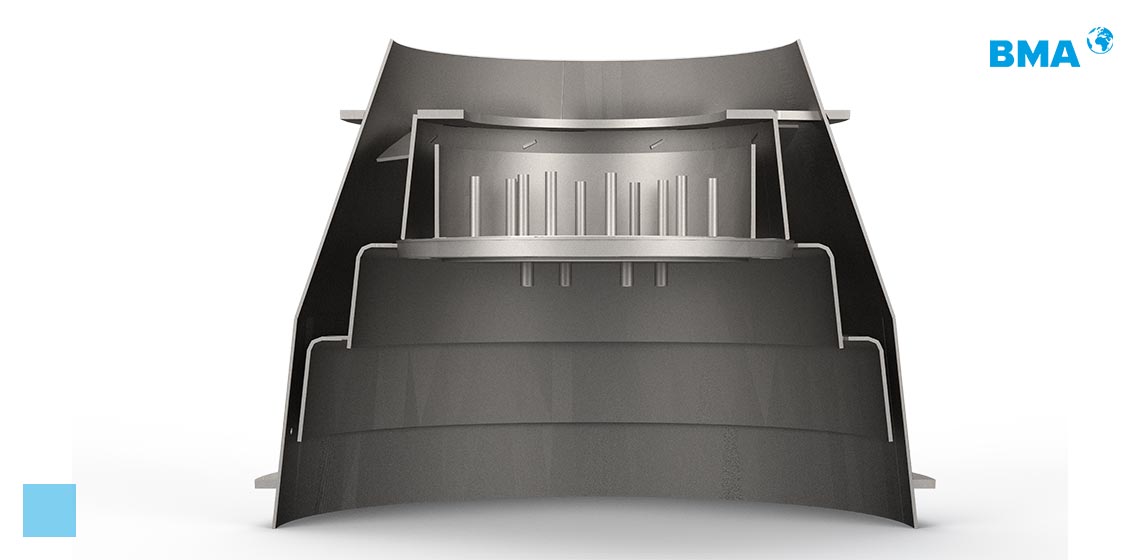

Product distributor

For a high throughput and top quality

The rapid yet gentle heating of viscous massecuite in our stepped Turbo-3 massecuite distributor prepares it perfectly for centrifugation. Some syrup is already separated at the preseparation stage, permitting higher throughputs than with a traditional conical centrifugal basket and therefore greater efficiency in plant operation. With the double-angled basket, sugar crystals of maximum purity and quality can be produced. The patented elliptical openings in the basket shell also play a major part in this.

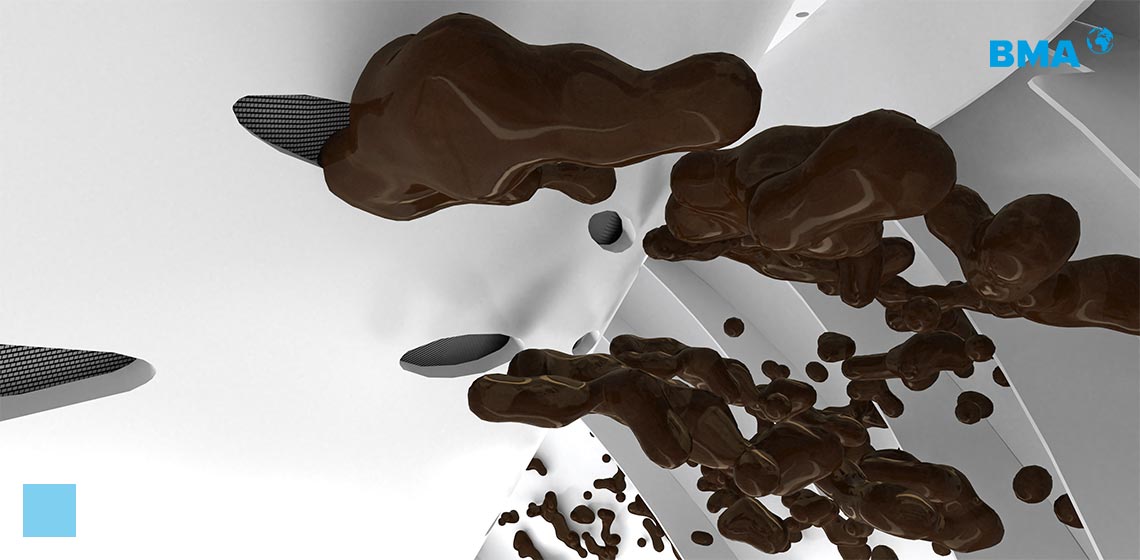

Elliptical openings

After this process, the mass collects along the basket wall, moving upwards, and the separation of crystal and molasses starts.

The molasses or syrup is discharged into the molasses chamber through the elliptical holes in the basket. It will then flows out of the machine through one or two ducts, depending on whether the machine is equipped with syrup separation. Wash water is applied to the crystals as they continue to move upwards along the basket wall.