The next generation of massecuite pumps (DRP) from BMA

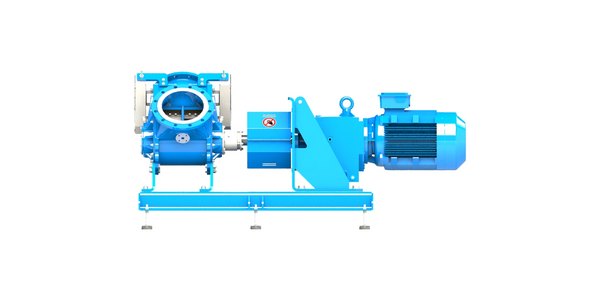

After many months of development, BMA will be presenting a new generation of massecuite pumps in summer 2018: the DRP series. Like its predecessor, the new series has been designed entirely with the requirements of the sugar industry in mind.

When the going gets tough

The new DRP series demonstrates its strengths in the conveying of highly viscous media in sugar production, ensuring the homogeneity of material flows at the crystallisation and separation stages.

The new DRP series is ideal for these media:

-

A/B/C crystal suspensions

-

A/B/C seed massecuites

-

Affination massecuite

-

Refined-sugar massecuite

Continuity in the sugar house

The operating principle of the new massecuite pumps from BMA is that of a rotary piston pump. It ensures smooth running and very homogeneous conveying of massecuites and suspensions from A to B. The new DRP pumps are also particularly gentle on the crystals, while offering an impressive performance in the range 2 to 120 m³/h.

Maintenance is kept to a minimum, thanks to the new DRP series’ sturdy design, select materials and excellent running properties. With their variable settings of the feed and discharge branches at 0°, 45° and 90°, the pumps are easy to integrate with the local infrastructure. The pumping unit is available with pressure levels of 6 and 10 bar.

Whatever media you wish to transport in the sugar house, the new DRP-series massecuite pumps from BMA will keep product flows moving.

Key benefits at a glance

-

Conveying at low speed is

gentle on the crystals. -

Excellent performance

and pump volume in the 2 to 120 m³ /h range. -

Smooth running properties

thanks to dual chamber principle.

Range of sizes

| Size | Feed pressure | Length L | Width W | Hight H | Connections | Flow volume | ||

|---|---|---|---|---|---|---|---|---|

| DRP10 | 6 | 2,350 | 750 | 1,000 | DN 150 | 1 - 10 | ||

| DRP10 | 10 | 2,350 | 750 | 1,000 | DN 150 | 1 - 10 | ||

| DRP25 | 6 | 2,400 | 925 | 1,150 | DN 250 | 2.5 - 25 | ||

| DRP25 | 10 | 2,550 | 925 | 1,150 | DN 250 | 2.5 - 25 | ||

| DRP45 | 6 | 2,600 | 1,000 | 1,200 | DN 300 | 5 - 45 | ||

| DRP45 | 10 | 2,900 | 1,000 | 1,200 | DN 300 | 5 - 45 | ||

| DRP75 | 6 | 3,100 | 1,300 | 1,450 | DN 400 | 8 - 75 | ||

| DRP75 | 10 | 3,100 | 1,300 | 1,450 | DN 400 | 8 - 75 | ||

| DRP120 | 6 | 3,250 | 1,500 | 1,500 | DN 500 | 12 - 120 | ||

| DRP120 | 9 | 3,330 | 1,500 | 1,500 | DN 500 | 12 - 120 |

Dimensions are for guidance and approximate planning only; they should be taken as reference values. The final dimensions are subject to a pump’s specific configuration and can be found in the specifications. Length measurements are for pumps without an external fan. Height and width measurements are for a 45° setting of the branches and subject to change depending on the base plate. Dimensions do not include infrastructure connections.