Precise planning, coordination and implementation are key factors in the success of a sugar factory upgrade. BMA takes a central role in this respect in a project for Lantic Inc. Commissioned by the Canadian sugar producer, we are in charge of the detailed engineering for an upgrade of the refinery at Montreal.

BMA successfully completes detailed engineering for Lantic Sugar refinery

Capacity upgrade of sugar process in Montreal thanks to comprehensive planning

BMA helps Lantic to increase sugar output

Demand for refined sugar is high in Canada. With the upgrade of its Montreal refinery, Lantic is planning to increase output by 100,000 t per year.

BMA is planning main and ancillary equipment for sugar refinery

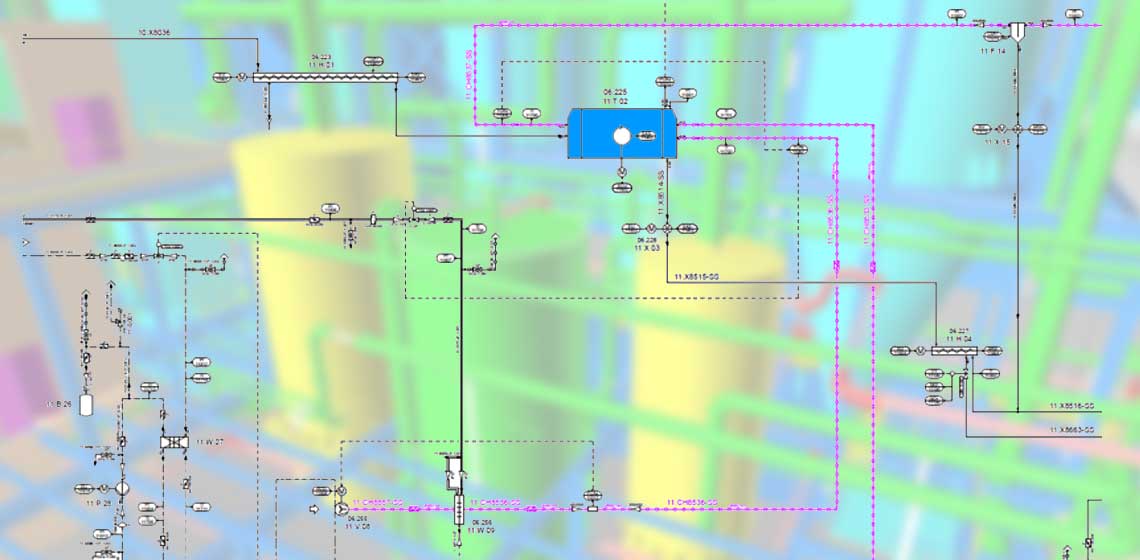

BMA is the process owner of the whole upgrade project. Tasks include the preparation of mass and heat balances and the accurate dimensioning of the main and ancillary equipment. We will also act as coordinator for the subcontractors, to ensure efficient collaboration of all parties involved.

Detailed engineering from BMA: meeting specific requirements

Detailed engineering from BMA includes all steps of the sugar process – from raw sugar melting to juice purification, filtration, decolourisation, evaporation and crystallisation to sugar drying.

Our focus is on meeting the sugar factory’s specific requirements. This involves preparation of an accurate plant configuration to ensure all plants, machinery and equipment are perfectly integrated into the existing building. This will ensure smooth operation of the sugar process.

Partnership between Lantic and BMA strengthened

We completed the detailed engineering in June and have planned all technical aspects of the refinery upgrade. The project has further strengthened the long-term partnership between Lantic and BMA, which has involved the supply, installation and commissioning of machinery and equipment.