Basic engineering, detailed engineering and the piping design for the sugar house: those were our job specifications from the Yunan Yinmore Group in China. In November 2017, BMA completed the 4,000 t/d refinery project and handed over all documentation.

01.07.2018

Planned to the last detail

Engineering Network delivers tailor-made solutions – such as in China

It is just one of last year’s many success ful engineering projects that are impressive evidence of BMA’s expertise. Projects of this type comprise three levels of service packages.

The first step: basic engineering

As part of the first-level package, basic engineering, we develop mass and heat balances. These form the basis for dimensioning the main and ancillary equipment. BMA then uses the results to prepare process flow diagrams (PFD), which show how the individual components and subsystems are connected to form the plant.

BMA records all data in the COMOS engineering database. This is the central source of information for all engineers working on a project. It provides access to the latest project data at any time.

In the next step, we develop a layout concept for positioning the plant components in the main building and draw up the relevant plans. Now there is sufficient information for describing the items of equipment in more detail. We write specifications, which are needed to request prices, terms of delivery, and technical equipment details.

At the same time, we work on the process description, which will form the basis for automation of the plants by our automation experts. It defines the role of each major piece of equipment, as well as the rules for safe and smooth operation and for monitoring.

The next level: detailed engineering

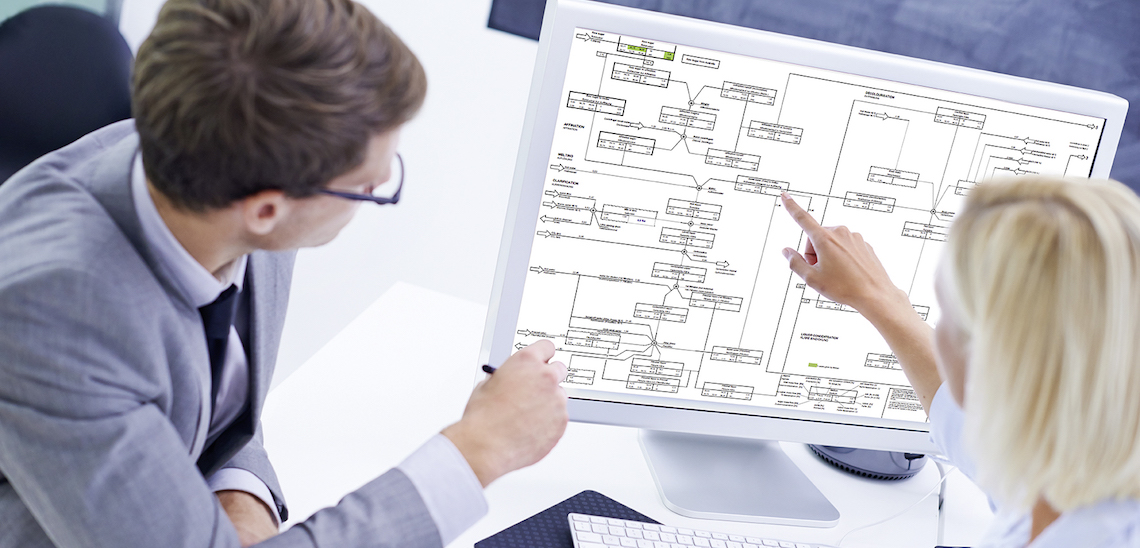

Our second-level service package is detailed engineering. This is where the PFDs are used to draw up, step by step, so-called piping and instrumentation diagrams, or PIDs for short. These documents clearly show how sugar technologists, plant engineers and automation experts work together. They contain a multitude of details, such as about mechanical and electrical connections between plant components, about pipe classes, sensors and controls, and about valves and insulation.

Working out and compiling all this essential information for the PIDs is the main task within the detailed engineering package. Once again, the COMOS database serves as the central repository for all details.

All good things come in threes: the piping design

Together, the PIDs, the details about the main and ancillary equipment, the finalised layout and positioning plans, and the information on construction form the basis for the third-level package: the piping design. Using our AutoCAD Plant 3D planning software, we include all plants and equipment in a 3D model, position them and connect them with pipes.

At a later stage, this model serves to generate the data needed to manufacture and assemble piping and cable trays. There may be several thousand separate documents, as was the case with the refinery for the Yunan Yinmore Group.

We make extra sure – with the FEM software

The safety of your plants is especially close to our heart. Which is why we check the strength of all large pipes that conduct steam or vapour using FEM (finite element method) software. The report that contains the analysis results is one of the final documents for piping design.

For the implementation of projects of this type, BMA relies on its international Engineering Network. It bundles the individual skills, expertise and specialist knowledge of our technologists, automation experts, process and plant engineers, allowing us to form international teams who can handle virtually any task relating to beet and cane sugar, sugar refineries, or sweeteners.