Magyar Cukor, a sugar producer based in Kaposvár, Hungary, has ordered seven E1810 batch centrifugals from BMA. These machines have a range of benefits, among them their exceptional reliability during operation.

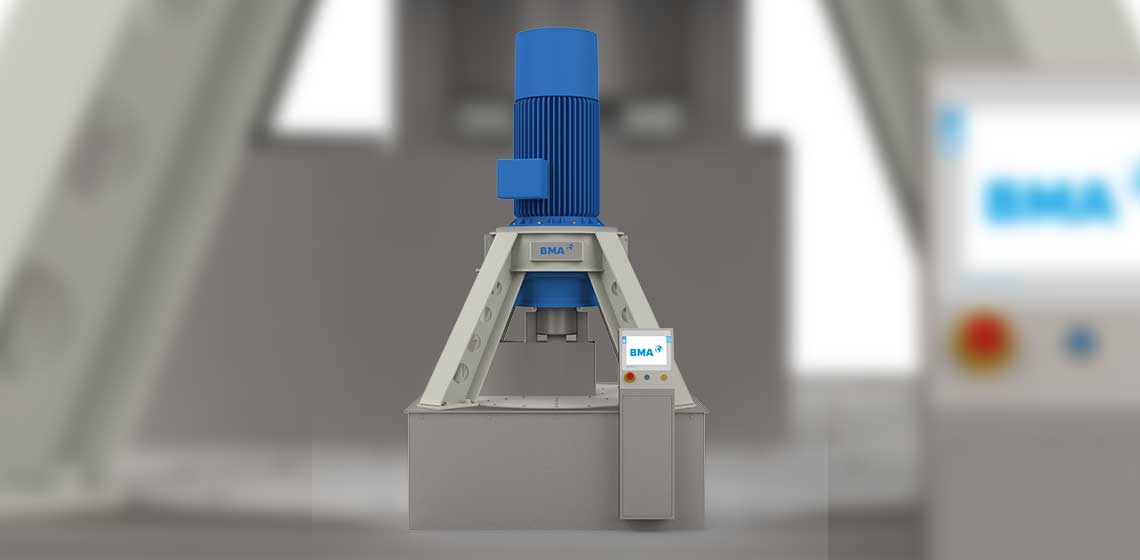

The E1810 centrifugal – a model of reliability

Magyar Cukor orders E-type centrifugals from BMA

Centrifugals for Agrana at international sites

In May 2022, Magyar Cukor ordered seven E1810 batch centrifugals from BMA. The sugar producer is majority-owned by the Vienna-based Agrana Group. BMA has already manufactured E-series centrifugals for other Agrana sites in Austria, the Czech Republic and Bosnia and Herzegowina.

Delivery of these machines is planned for the end of February 2023. This generous time frame is the result of supply problems, with bottlenecks at present affecting particularly the electronic components for the centrifugal control system.

E-series centrifugals: designed for a long service life

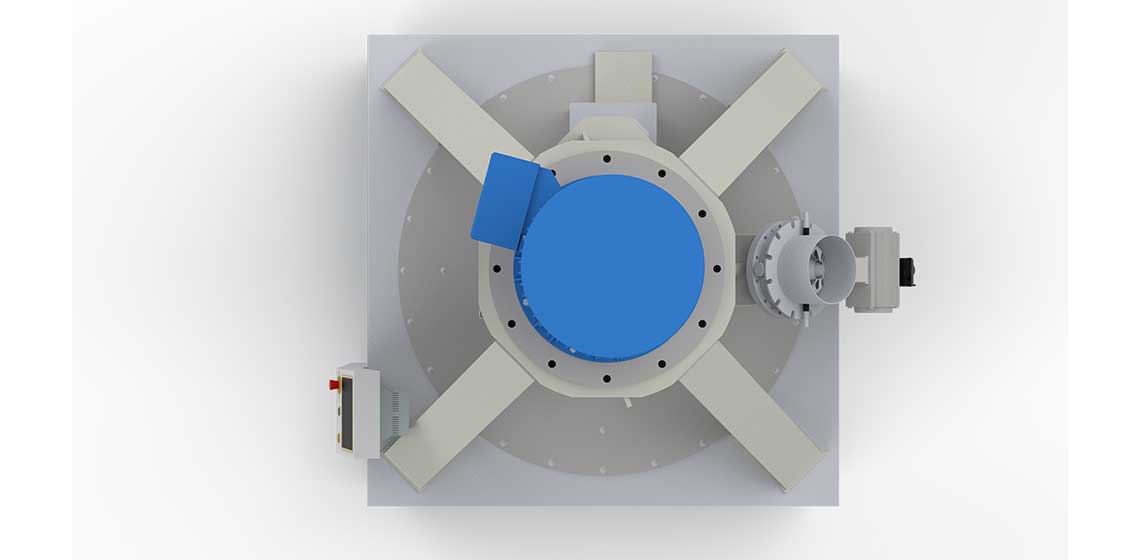

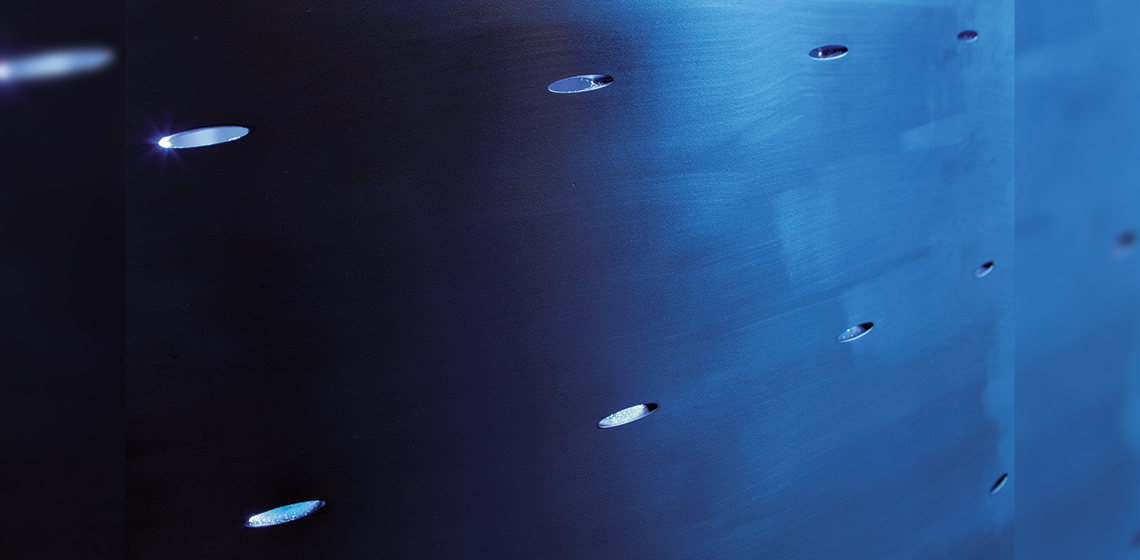

Four of the centrifugals will be used to process white sugar massecuite, the other three for raw sugar. One distinguishing feature of the E series are the non-standard elliptical discharge openings, which reduce material stress. The centrifugal baskets therefore have a longer service life, although the basket walls are thinner.

The so-called basket hub, which connects the drive shaft to the basket, is designed in such a way that it was possible to simplify the design of the discharger. It only makes a pivoting movement now, but no longer moves vertically. One resulting benefit is that fewer components are required.

Centrifugal sensor for automated control

The only moving parts in the syrup separation system are the butterfly valves at the outlet. This design permits a clear separation of green and white run-off, whose respective shares can be adjusted as required.

The contactless electronic level sensor detects when the final sugar layer thickness in the basket is reached. It also monitors the build-up of the sugar layer and controls it by adjusting the butterfly valve opening as required for a sufficient massecuite flow. The filling level of the strike receiver can be included in this control mechanism as an additional parameter.

Hungarian sugar factory values the strengths of the E1810 centrifugal

The E-series centrifugals from BMA have already demonstrated their many benefits in several Agrana sugar factories. From next year, they will be showing their particular strengths in Hungary too.