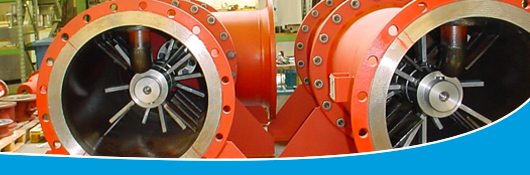

The BMA massecuite mixer permits optimum mixing of heated molasses and cooling massecuite. Reducing the crystal content and raising the product temperature diminishes the viscosity of the massecuite, subject to requirements, by up to 1/5 of the original figure.

The BMA massecuite mixer produces easy-to-centrifuge massecuite and replaces other re-heating equipment of the Green-Smith type which quite often operated inefficiently and at rather high costs. The mixer is installed vertically or horizontally in line between the final cooling crystallizer and the centrifugal station.

Features and advantages:

- Higher sugar yield and higher dry substances

- Better centrifugation

- Viscosity of the massecuite can be adjusted by setting the temperature and the quantity of recirculated molasses

- Flexible in-line installation

- Horizontal or vertical installation

- Small floor space required

- Low maintenance requirements

- Low capital cost compared to other systems