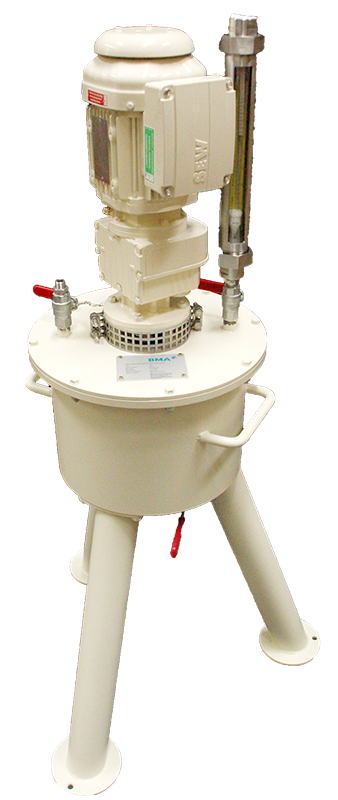

- Volume: 10 litres

- Drive power: 0.55 kW (explosion proof, IP 65)

- Feed through easily accessible intake

- Discharge through central outlet valve

- Hardened stirrer blades for increased resistance to wear Screw-type legs for flexible installation

Slurry mill

Especially for seeding as a preliminary stage of product crystallization proper, the use of a slurry suspension is now state of the art. BMA's supply line of crystallization equipment also includes a slurry mill operating by the ball mill principle, using hardened steel pebbles.

The use of seed crystals of a defined size and number to stimulate crystallization of sugar solutions is a decisive improvement over former graining methods (e.g. introduction of air at high supersaturation). Wet milling of sugar crystals in slurry mills together with isopropyl alcohol under standardized conditions produces a slurry suspension which gives excellent results in terms of uniform crystal size and crystal size distribution. The use of a slurry suspension in the graining phase essentially improves the whole crystallization process and makes it more reproducible. When varying the quantity of slurry added, it also yields a defined crystal size in the finished product at optimum supersaturation.

Benefits