Continuous and batch-type pilot tests in the BMA research centre serve to verify the results of laboratory tests, and to determine and optimise process parameters. Pilot test results serve as proof of technical feasibility of process steps on an industrial scale and for the configuration of the apparatus and machinery.

Pilot-scale testing is an important step in the planning of a large-scale crystallisation plant. Crystallisation trials at the research centre can be combined with additional tests such as on heat transfer or the sedimentation behaviour of crystal suspensions. In these scale-ups, larger volumes of massecuite and mother liquor are produced, permitting specific separation and drying tests. The separated mother liquor is used for further tests on crystallisation behaviour and on increasing output. Based on the results of laboratory and pilot-scale testing, the basic concept marks the first step in the planning stage of a crystallisation plant.

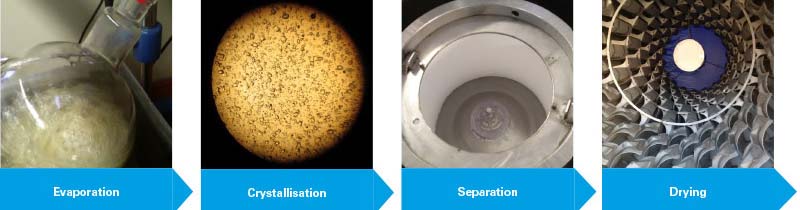

For technical implementation, machinery, apparatus and process parameters are adjusted to match product-specific characteristics. Relying on the documentation from basic or detailed engineering, BMA can supply equipment to implement an entire project, from evaporation to crystallisation, to separation, and to drying.