For about one year, BMA has been assisting Wanze sugar factory, a member of the Südzucker Group, in a special project: the integration of raw sugar from cane into their production process, which has been exclusively based on beet so far. To realise this ambitious project, the Belgium-based sugar factory charged us with the concept study, the engineering work and the supply of the necessary equipment.

For Wanze sugar factory: BMA realises refinery operation by concept study, engineering, and equipment

3D scan allows for optimal project planning and implementation in Belgium

Optimisation of equipment needs thanks to an individual solution from BMA

The sugar factory’s focus is on keeping any additional requirements regarding equipment as low as possible. For this purpose, BMA has developed a customised solution, where the sugar factory’s existing plant equipment is optimally used, and new equipment efficiently integrated.

Concept study from BMA: the basis for production expansion

In the concept study, BMA has thoroughly analysed the factory’s requirements. On the one hand, our solution considers the operational, technical as well as economical needs at Wanze, while it identifies, on the other hand, the necessary steps required to integrate raw sugar from cane into the production process. In this way, BMA’s concept study forms the basis for the implementation of refinery operation.

Basic and detailed engineering from BMA: elaboration of project information

BMA’s basic and detailed engineering are based on the results of the concept study. We have specified and refined project planning by selecting suitable BMA equipment and preparing detailed technical specifications for merchandise (like pumps), heat and mass balances as well as time and cost schedules for BMA equipment.

Our design drawings and planning services are the basis for the actual procurement and manufacture, and the installation and commissioning of the equipment. Moreover, BMA has provided process flow diagrams to visualise the process and to illustrate how the various elements of expanded production are smoothly interacting.

3D scan: key factor for efficient integration into existing infrastructure

The major challenge is to ensure the integration into the equipment already existing at Wanze. BMA could gather the existing plant-related and infrastructural details by way of a precise 3D scan of the overall sugar factory. This information decisively contributed to an optimal planning and implementation of the expanded plants, while efficiently utilising the space available.

Commissioning of BMA equipment before the new campaign

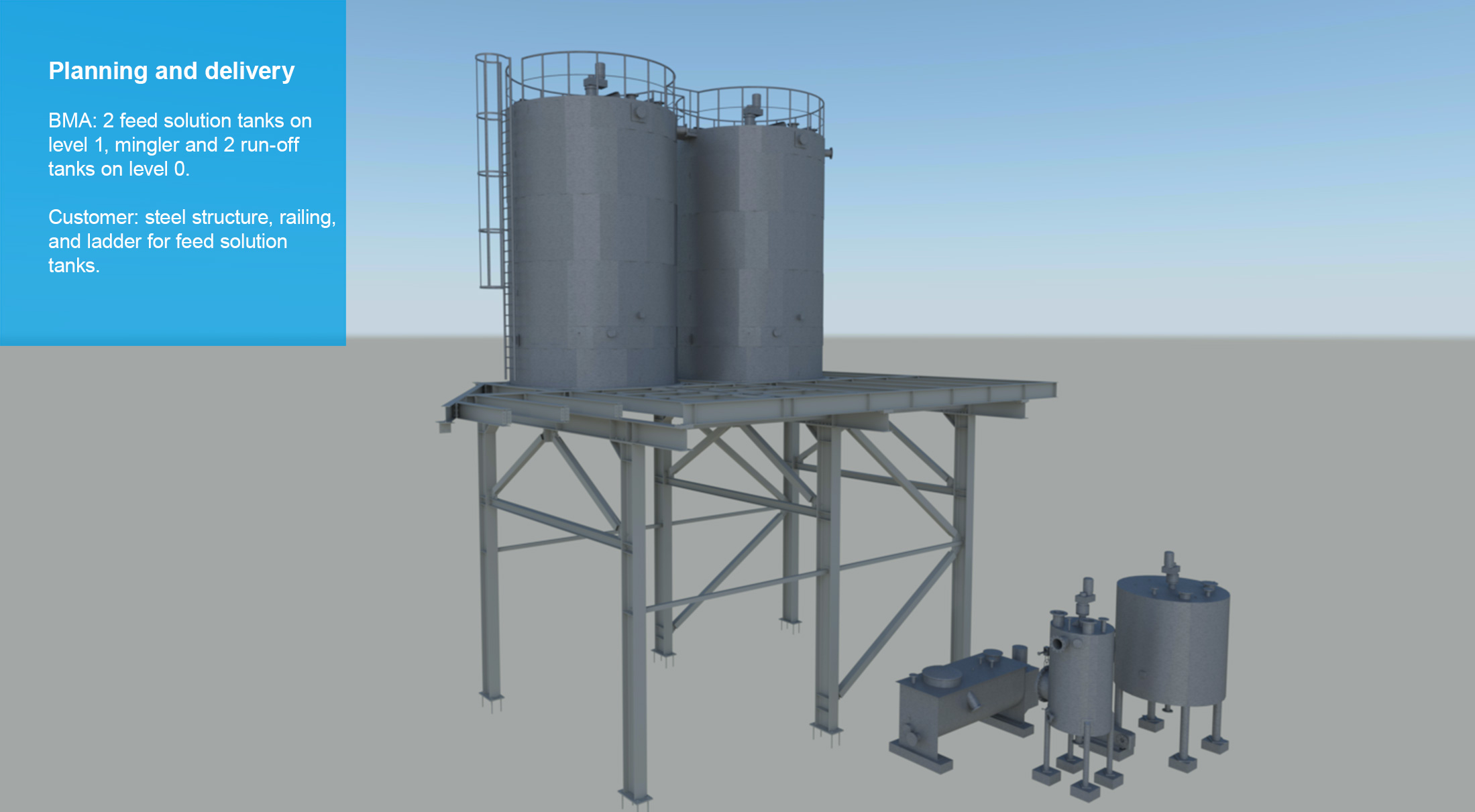

Meanwhile, BMA has manufactured and delivered the equipment for the expanded production process. This includes the tank for large-scale raw sugar melting, a revolving-arm mingler, two big feed solution tanks, and three smaller tanks including one each with agitator for molasses and sugar to be melted from low-raw sugar crystallisation.

In just one year – and before the beginning of the beet campaign in September – BMA has successfully completed the engineering, supply, and supervision of assembly for the integration of raw sugar from cane into the production process for the Wanze sugar factory. Commissioning was successfully performed in spring 2024.