Operation of the new juice purification station at the Znamenskiy sugar factory in Russia is based on the pre-carbonatation principle. What makes this method so special? And how can beet sugar factories and sugar refineries benefit from state-of-the-art physical and chemical juice purification?

01.07.2019

A good principle

A concept for juice purification from BMA

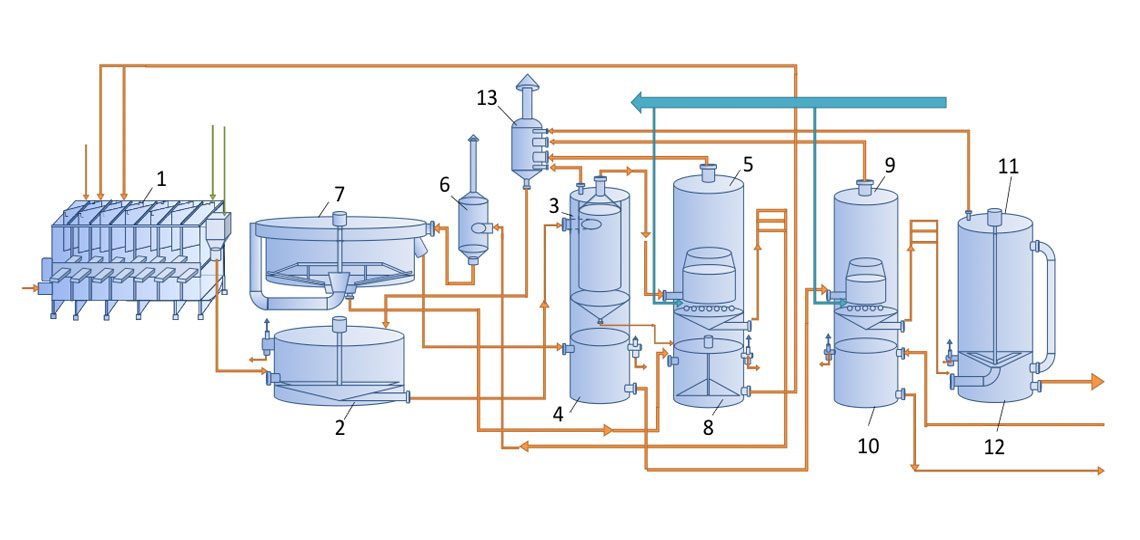

A Brieghel-Müller apparatus (1) is used for gradual cold and hot preliming of the raw juice. The prelimed juice flows down into the tank for cold main liming (2), where it is desludged.

Cold and hot main liming

Cold main liming takes place in a cylindrical apparatus equipped with an agitator, and hot main liming in the upper section of a combined apparatus. This upper section (3) is cylindrical in shape and has a conical bottom. It is equipped with a central pipe through which the juice enters the apparatus, and with an agitator. The lower section (4) consists of a tank for collecting the clarified juice discharged from the separator for first carbonatation juice. After hot main liming, the juice is transported into the apparatus for first carbonatation (5). Desludging of the apparatus (3) is effected in the carbonatation juice concentrate tank (8).

First carbonatation

The first carbonatation occurs in the upper section of a combined apparatus. This upper section (5) is cylindrical in shape and has a conical bottom. It is equipped with a central arm for repeated stirring of the juice, and with Richter tubes for optimum distribution of the carbonatation gas. The lower section (8) consists of a tank for collecting the carbonatation juice concentrate discharged from the separator. It is equipped with an agitator. The first carbonatation juice flows down through the carbonatation apparatus, first into the deaerator (6) and then into the separator (7). Desludging of the apparatus (5) is effected in the carbonatation juice concentrate tank (8).

Separator for first carbonatation juice

In the cylindrical single-stage separator with a conical bottom that is equipped with an agitator, the unfiltered first carbonatation juice is separated into clarified juice and a viscous suspension.

A flocculant solution is automatically added for more efficient juice purification in the separator.

Second carbonatation

The second carbonatation occurs in the upper section of a combined apparatus. This upper section (9) is cylindrical in shape and has a conical bottom. It is equipped with a central arm for repeated stirring of the juice, and with Richter tubes for optimum distribution of the carbonatation gas. The lower section (10) serves to collect the thin juice pumped to the evaporator station. The second carbonatation juice flows down from the carbonatation apparatus into the secondary reaction tank (11). The vapour from the first and second carbonatation apparatus is fed into the scum collector (13). Desludging of the apparatus (9) is effected in the second carbonatation juice tank (12).

Secondary reaction of second carbonatation juice

The secondary reaction occurs in the upper section of a combined apparatus. This upper section (11) is cylindrical in shape, has a conical bottom and is equipped with an agitator. The lower section (12) consists of a tank for collecting the second carbonatation juice discharged from the secondary reaction tank.

Use of this juice purification station helps save the costs for additional equipment (pumps, heat exchangers) by exploiting gravity and integrating a separator. As shown in the illustration, these main pumps are used: two pumps each for main liming juice, for clarified juice from the separator, and for second carbonatation juice. This results in power savings. There is no need for additional equipment during the campaign. Maintenance and repair costs after the beet campaign are lower.

Juice purification 1

The benefits of using a separator:

- Higher purity and better quality of the thin juice; lower-quality sugar beets can be processed without quality losses

- Requires less CaO

- Easy to operate

- Minimum use of automation equipment; no maintenance or repair costs for shut-off devices and control valves

- Higher density of carbonatation juice concentrate (more than 1.25 g/cm³) thanks to flocculant use

- Lower investment and operating costs than with use of concentrating filters

Juice purification 2

The benefits of exploiting gravity and using combined apparatus:

- Only few equipment items are needed; no additional equipment for desludging processes (collection boxes with agitators, pumps and sand separators)

- Short residence time of the products in the plant

- Special design permits low use of lime and lime kiln gas

- Juice purification station has a small footprint