Raffinerie Tirlemontoise in Tienen, Belgium, will in future be processing all beet in an extraction tower from BMA. The new extraction plant is designed for a slice rate of 14,500 t/d. BMA’s scope of delivery comprises engineering, assembly including the steel structure, and commissioning.

Raffinerie Tirlemontoise opts for extraction tower from BMA

Tienen sugar factory: high capacity, considerable CO2 savings

Kickoff for BMA extraction tower construction

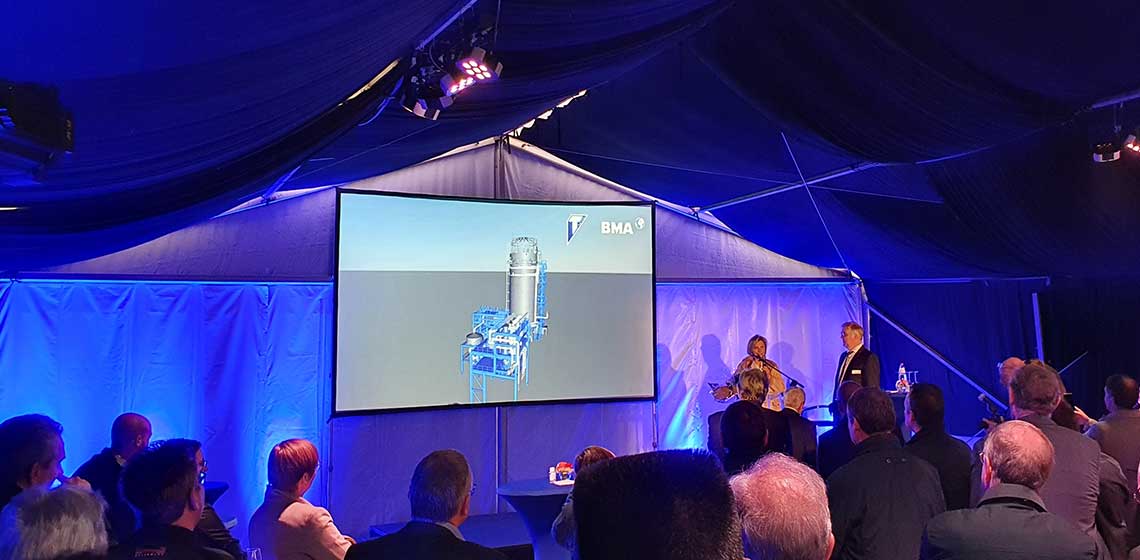

On 22 October 2021, the Flemish minister for economy and innovation, Hilde Crevits, and the managing director of Raffinerie Tirlemontoise, Jan Inglés, together kicked off the project at the construction site. The extraction plant from BMA will be replacing two RT diffusers. Raffinerie Tirlemontoise is a company of the Südzucker Group and operates sugar factories in Tienen and Wanze.

Extraction plant for more efficiency and sustainability

The sugar factory is expecting the new extraction plant to annually reduce CO2 emissions by 5,744 t and water consumption by 150,000 m³. For the implementation, it has received one million euros in subsidies from the Flemish government – strong evidence of the sustainability of the solution. The sugar factory is expecting the new extraction plant to annually reduce CO2 emissions by 5,744 t and water consumption by 150,000 m³. For the implementation, it has received one million euros in subsidies from the Flemish government – strong evidence of the sustainability of the solution.

Several design scenarios, optimum solution

What is the target slice rate? Should a capacity increase be included as an option? How can maximum sugar output be ensured? Discussions about the design of the extraction tower and the countercurrent cossette mixer were held even before the contract was awarded.

For BMA, close collaboration and dialogue with its customers are key to a successful project. Which is why the BMA team is committed to detailed consultations, to offer customers the optimum solution. With its extensive knowledge of the production process and equipment design, BMA was able to present several design scenarios including their benefits.

Another outcome of the consultations was an even higher processing capacity for the extraction tower. With the option of a future capacity increase, this solution fully meets the sugar factory’s high expectations.

Stainless steel extraction tower from BMA

In addition to equipment size, the choice of material is another major issue. Durability, simple maintenance and maintenance cost are as crucial as the process data. The entire extraction tower and the countercurrent cossette mixer are made from solid stainless steel, from the shaft to the vessel. That is in line with developments in the Western European sugar sector and complies with food industry safety standards.

Extraction tower from BMA: commissioning scheduled for 2023

Additional solutions provided by BMA will be the switchgear cubicle for the extraction plant and the drive control – as well as engineering, delivery and building of the steel structure. All assembly work will be performed by BMA.

With the help of the BMA team, the extraction tower will be commissioned in time for the 2023 campaign.