The food industry is always on the lookout for new ideas and concepts for enhancing the nutritional value of foodstuffs. One major contribution comes from BMA.

01.07.2019

Sweet as sugar

Our expertise comes in handy where the group of polyols is concerned

If the formula of a foodstuff is changed so it can be labelled as sugar-free, alternative sweeteners have to replace sucrose or glucose-based sugar sources. BMA has registered growing market interest in this field, evidenced by the demand for technologies and processes for the production of crystalline forms of sugar substitutes.

A product group with attractive properties

Foodstuffs produced with sugar substitutes can taste and look much like those made with traditional formulas. Their sweetness combined with a low energy content and glycaemic index make these products very attractive for the food industry. And they are also of interest to the chemical industry when it comes to platform chemicals in green chemistry.

Like sucrose, sugar substitutes belong to the group of carbohydrates. From a legal point of view, they are sweeteners, classified as sugar alcohols because of their chemical structure, as shown in our table. They are often referred to as polyols.

One of the main characteristics of sugar substitutes is their sweetness. Although they are less sweet than sucrose – between 40 and 80 % depending on the product – the taste profiles of some sugar substitutes are very similar to that of table sugar.

Rare sugars becoming more common

On an industrial scale, sugar substitutes are produced by fermentation or hydrogenation of substrates consisting of renewable raw materials that contain carbohydrates (mono- or disaccharides). New synthesis methods also permit the production of so-called rare sugars. Although their specific properties are known, they have not been used in foodstuffs to date, due to a lack of availability. But that may change.

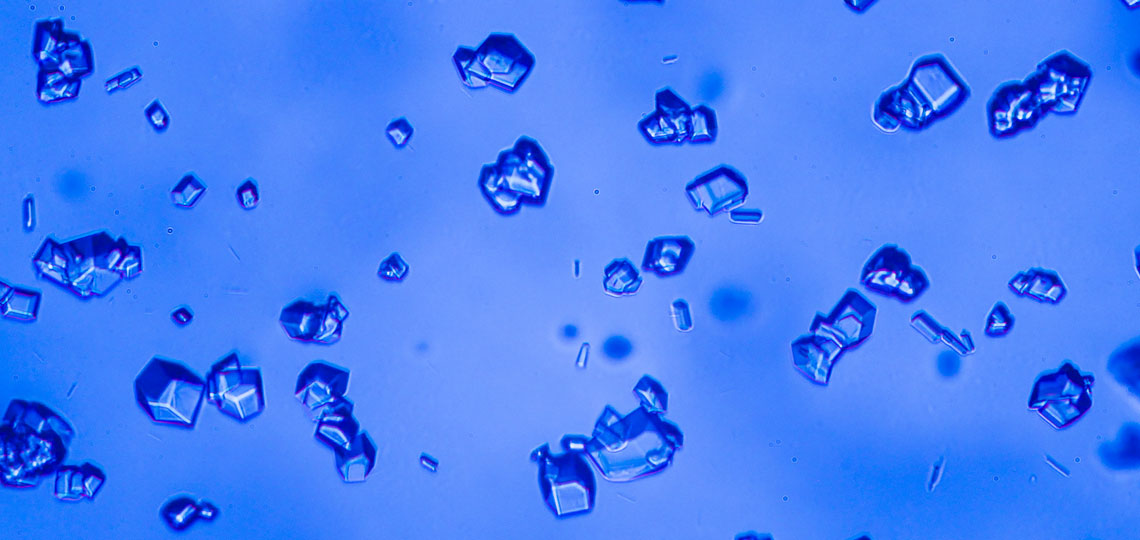

BMA has been a leading manufacturer of machinery, plants and equipment for the production of sucrose, glucose and fructose for many years. We successfully use our knowledge of processes and process engineering for polyol-group products. Because of their respective chemical structures, these materials have different chemical and physical properties. The individual sugars and sugar substitutes therefore also differ in terms of their solubility, crystal growth and shape. This requires different approaches in crystallisation and all other process steps.

From lab to research centre to production

In laboratory-scale tests, we determine material data, rate crystallisation properties, and assess whether transfer to the pilot-plant scale is possible. Continuous or batch-type pilot tests in the BMA research centre serve to verify the results of laboratory tests, and to determine and optimise process parameters. We use the findings as proof that process steps are feasible on an industrial scale, and for the configuration of apparatus and machinery. The engineering stage starts with the development of a technical concept, which integrates test results and customer-specific requirements.

As an integrated solution provider, we assist our customers in developing and implementing projects – from the laboratory to the research centre and ultimately to planning and delivering complete industrial plants. The focus is on the process steps evaporation, crystallisation, separation, and drying, which are just some of BMA’s core areas of expertise.